Application of chromite sand in foundry industry

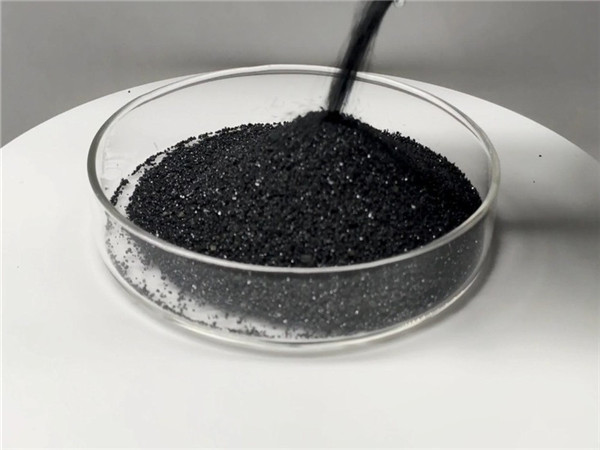

Chromite sand, also known as chrome ore sand or cr-sand, is a special sand for foundry. It is a natural spinel mainly made of chromite. It is crushed, ground, and sieved into a specified particle size, suitable for modeling (core making) sand .

Application of chromite sand in foundry

1. Chromite sand has excellent cooling performance. It does not reduce hot cracks, but can affect the temperature gradient and promote directional solidification without using cold iron.

2. Chromite sand is inert, so it does not react with other metal oxides. It will not be wetted by manganese steel. Manganese steel castings can be successfully used in chromite sand. If the mold is painted normally and the silica content is low, the iron olivine will not react.

3. Chromite sand has a small linear shrinkage, which is a factor that may cause sand inclusion in castings, so it can be used to mix green sand molds for large castings. The chromium ore is sintered with fine particles to eliminate metal infiltration, accompanied by cooling and high residual thermal strength.

4. Chromite sand is universal, it can be used together with various binders. Chromite sand has the same adverse effect on healthy non-silica sand.